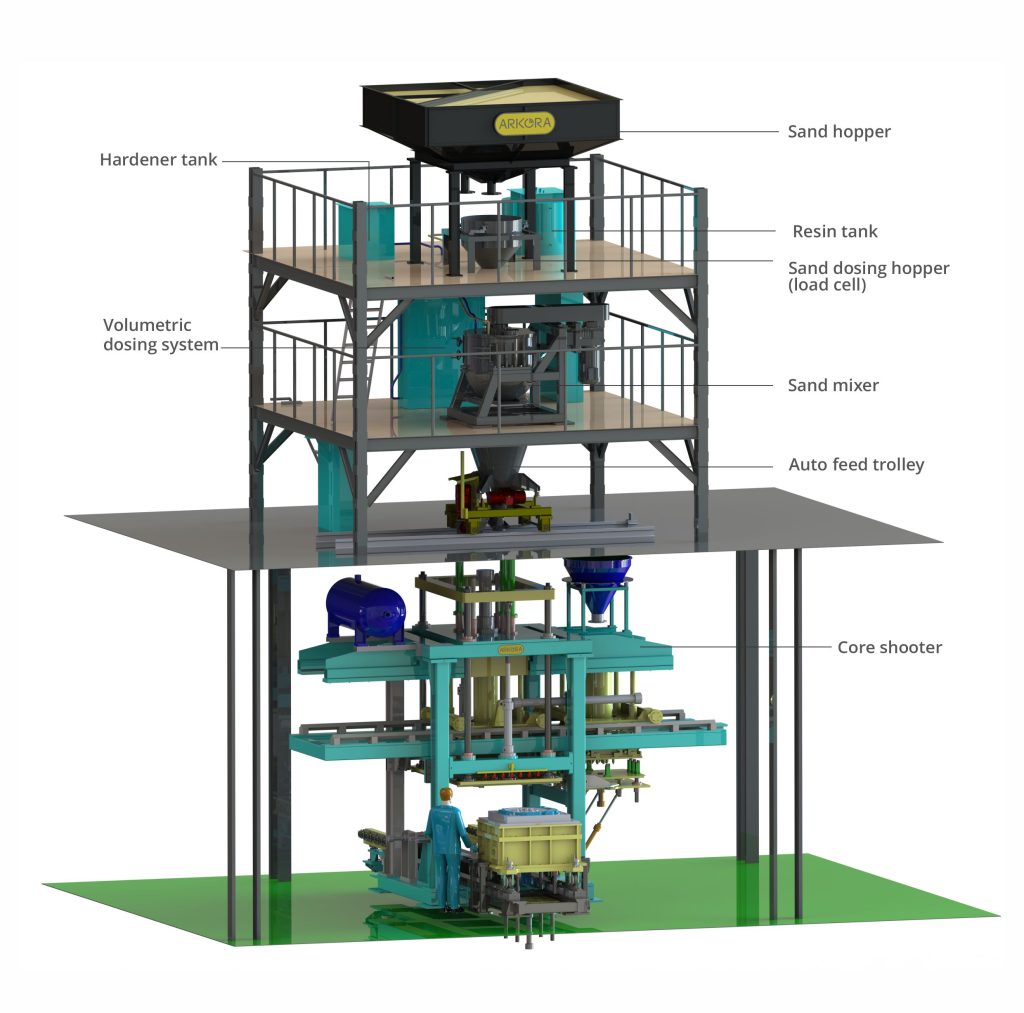

A COMPLETE SOLUTION FOR CORE MAKING

Cold Box Core Shooters with complete setup of all equipment which include mixer, sand trolley, hoppers, gas generators, electric panels etc.

Tailoring excellence to every project, ARKORA delivers complete core shop solutions designed to meet specific customer requirements. From initial concept to final execution, we provide high-performance systems precision-engineered for unique operational needs.

Robotic Core Painting

ARKORA made Robotic Core Painting Unit with core dipping in paint tank that is manufactured wholly as per customer-specific requirements. The robotic core painting unit can be used for painting individual cores or for core assembly painting.

FEATURES

- Special type of robots suitable for foundry environment

- The robotic arm can be rotated in any direction with max load-carrying capacity of core weight as per customer requirements

- Core can be tilted using gripper and fingers to avoid core paint accumulation in pockets Quick change system for gripper tool

- Auto inline viscosity control system

BENEFITS

- Uniform core painting can be achieved with robotic dipping process

- Automation in core painting with improved process control

- Industry 4.0 Integrated: Smart-ready connectivity for real-time monitoring and data analytics

- Reduced manual dependency in painting process

- Increased fettling output hence internal surface finish of casting is improved considerably

- Reduced casting defect due to core painting

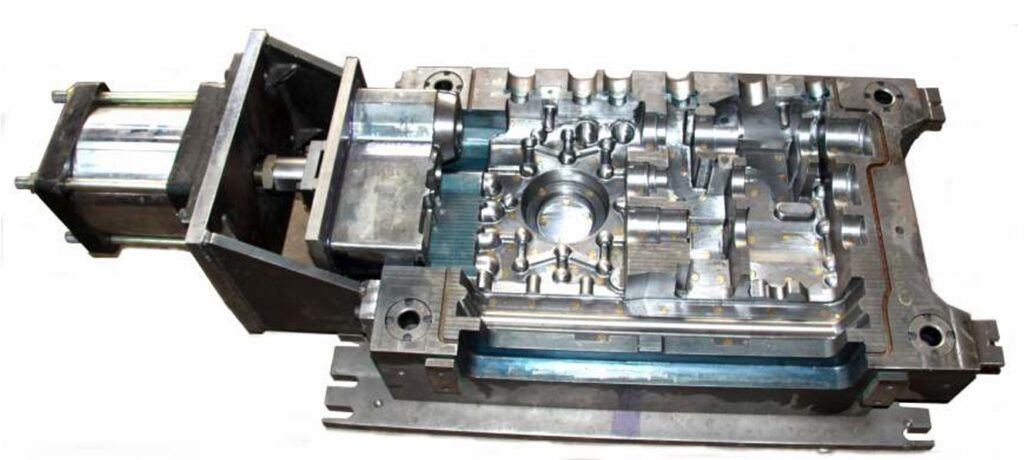

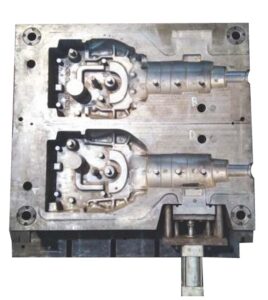

Tool Manufacturing

Core Box Tool Manufacturing: In-house capability of designing and manufacturing complete tooling solutions.

Core Box (Cold Box)

Core Box (Shell)

- Core boxes for cold box and shell shooter machines required to produce castings such as housing, transmissions, supports, cylinder blocks & cylinder heads, etc.

- Core boxes are manufactured in cast iron/spheroidal graphite iron/P20 material/aluminum.