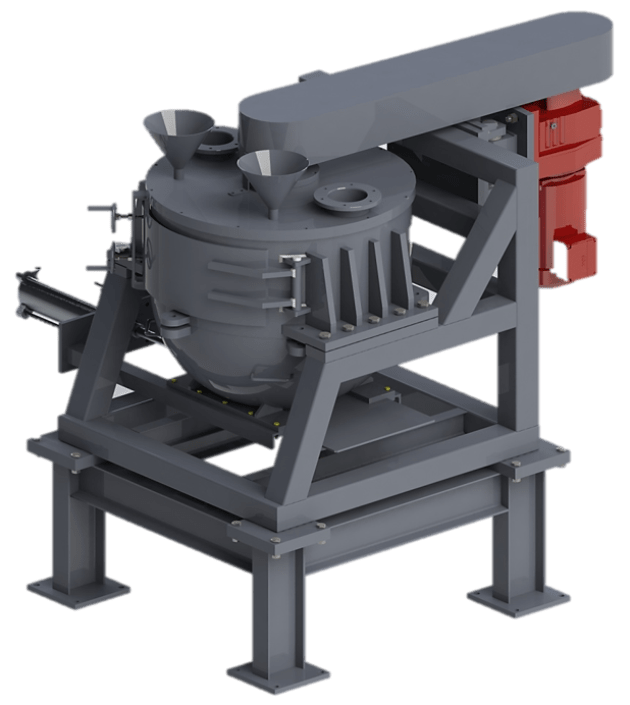

The ARKORA Bowl Type Intensive Mixer is a high-performance solution engineered for foundries that require absolute precision in sand preparation. Designed specifically for demanding core and mold applications, this mixer uses an optimized bowl geometry and a variable RPM system to deliver highly homogeneous sand mixtures.

Specifications

- Batch Capacity: 100 kg to 300 kg (Model dependent)

- Mixing Design: High-intensity bowl-type geometry

- Control Interface: VFD / PLC-controlled variable RPM for process customization

- Dosing Accuracy: Optional automatic additive dosing system

- Weight Measurement: Electronic sand weighing via integrated load cells

- Wear Protection: Specialized anti-wear coatings on all internal mixing components

- Discharge System: 100% sand discharge design to eliminate “dead zones”

Features

- Complete Homogenization: Achieve perfectly uniform sand quality for high-strength, defect-free castings

- Short Cycle Times: Optimized mixing action allows for faster production turnover and higher overall productivity

- Zero Wastage: The 100% discharge design ensures no sand is left behind, reducing material loss and preventing cross-contamination between batches

- Reduced Maintenance: The low-buildup design and wear-resistant coatings mean less time spent on cleaning and fewer costs for replacement parts

- Lower Binder Costs: High-accuracy dosing and weighing systems prevent the over-usage of expensive binders and additives

- Automation Ready: Designed for easy integration into modern, fully automated core shop layouts via PLC controls